Engineering Plastics

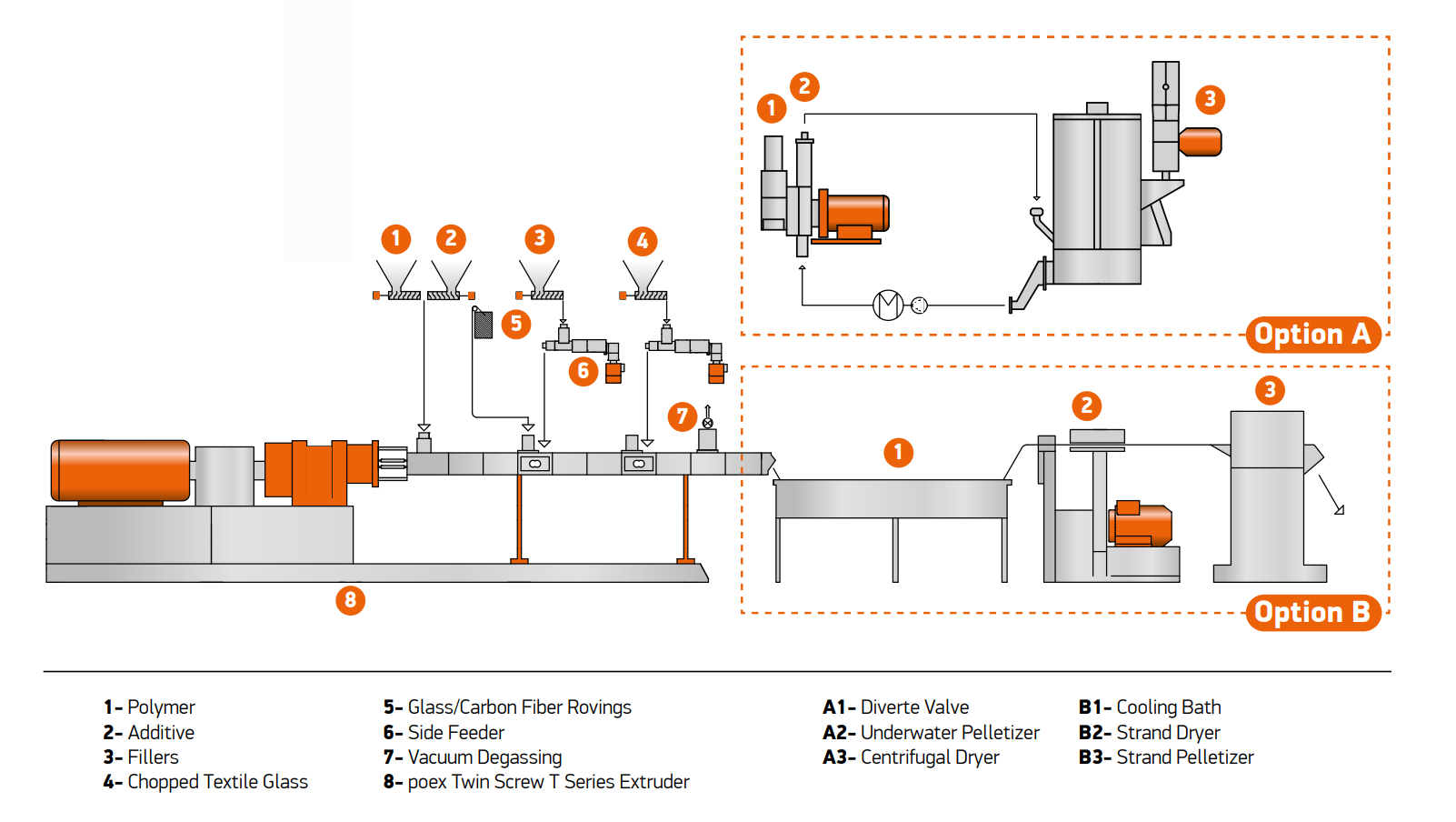

Compound application is the process of adding fillers and additives into molten plastic to produce a raw material with desired properties. Additives and modifiers give the plastic a certain color, fluidity, strength, etc. can add features.

One of the main application areas of poex twin screw extruders is engineering plastics applications. The excellent mixing properties provided with additives, fillers and reinforcing materials create products used in many fields.

In applications where impact resistance is required, fibers are reinforced to polymers. Mainly glass fibers are used, but other fibers such as carbon and natural fibers can also be bonded with polymer carriers. With the fiber reinforcement process to polymer blends, materials that are light but with high fracture and impact resistance can be produced.