Biopolymers

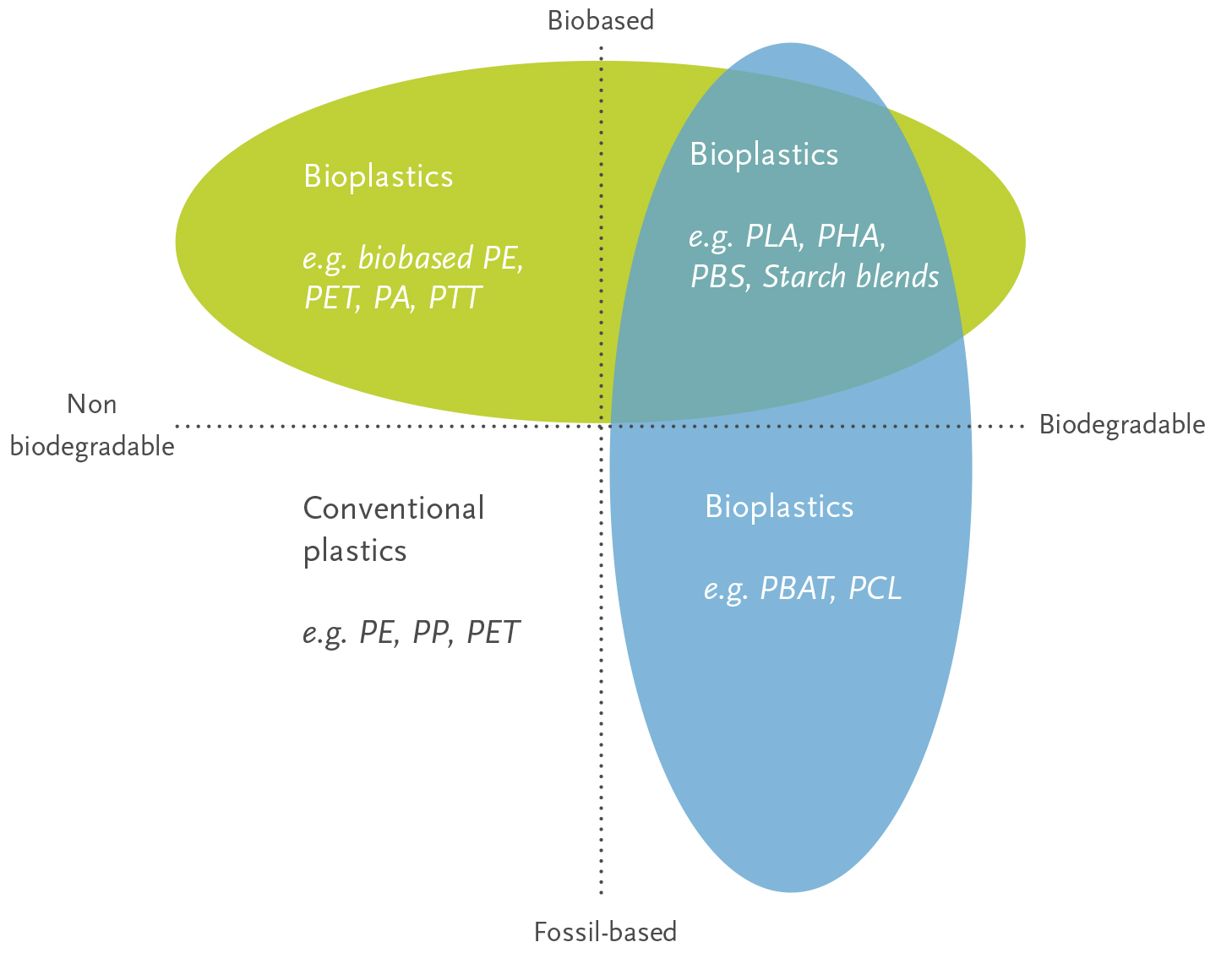

Bioplastics are plastics made from renawable bio-based raw materials.

Biodegradable and compostable thermoplastic starch (TPS) is produced from carbohydrate-rich plants such as maize, sugar cane or cellulose, most often by means of some type of plasticizer. Additionally, they can be mixed with a second bio-based polymer such as TPS, polylactic acid (PLA), polycaprolactone (PCL), polyvinyl alcohol (PVA), or synthetic polyesters. As a result, bio-based products are products that are composed – wholly or partially – of biological or renewable materials.

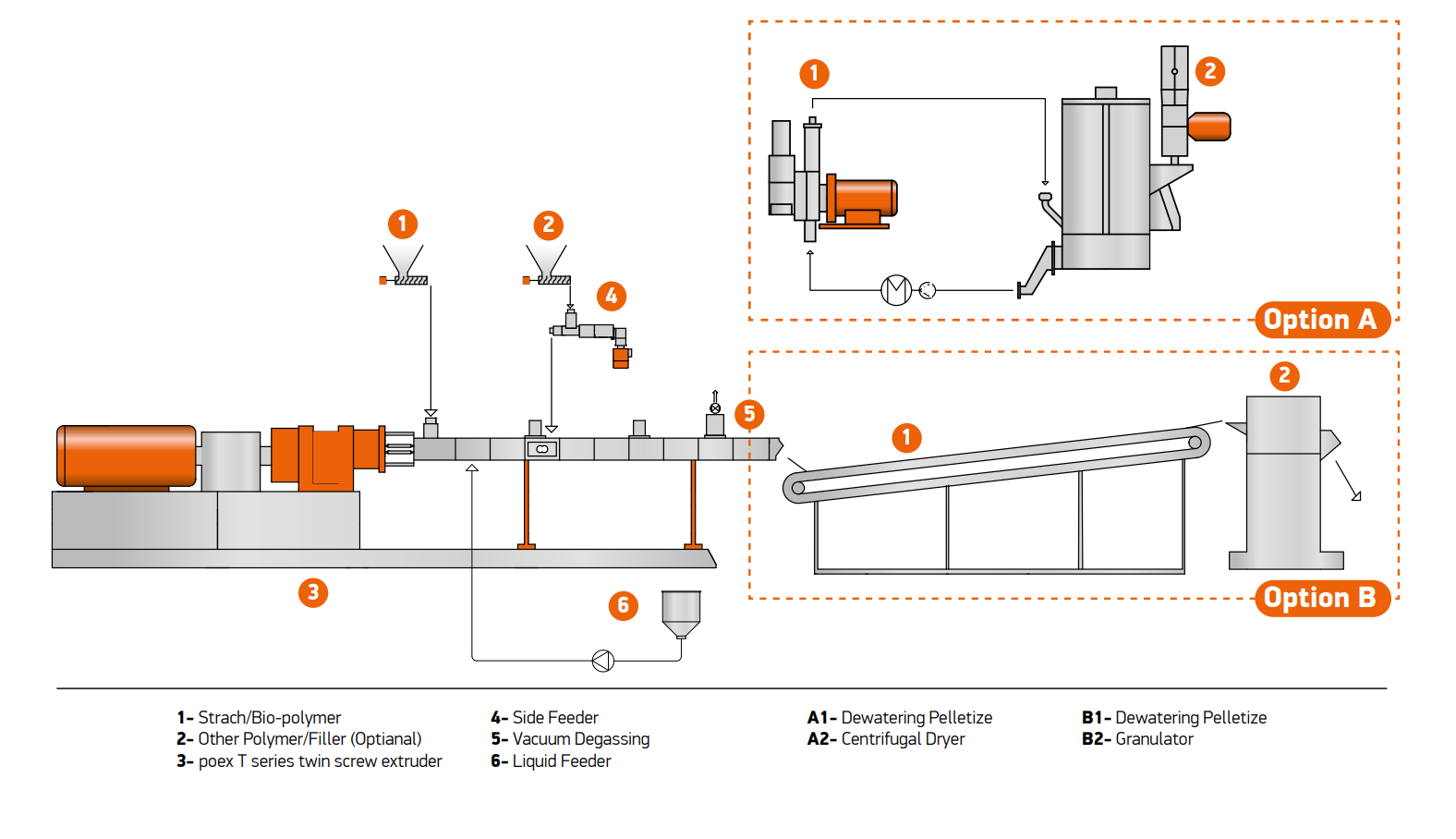

Polimer Teknik has extensive knowledge and experience in both the production of thermoplastic starch (TPS) and the design of compound systems used for biodegradable products.

General applications for the processing of biodegradable products

- Production of thermoplastic starch (TPS)

- Compounds of various bioplastic materials

- Compounds of plastics and biological materials

- Granular starch as a filler to improve the biodegradability of commodity plastics

- Pelletizing of PLA and PLA compounds

- Polylactide (PLA), PVOH, synthetic copolyester, PBS, PHA, PCL, CA

Compounding of biopolymers constitutes the first preparation process for the modification of plastics by means of extrusion following the production of the base polymer. Throughout the preparation, characteristic feature of the plastics can be selectively changed.

Hereby, it is adapted to the next process and targeted product characteristics. The plastic is melted inside the extruder where it is blended with additives, fillers, reinforcing materials or a combination of them. After homogenization and degassing of the compound, it is formed – usually as strands – by using a tool, then cooled and processed into plastic granules. In the compounding process, numerous effectors arise before processing and during it. Depends on the type of plastic, these factors are evident in variable degrees and affect it’s mechanical, thermal (chemical) and rheological properties as well.