poex T80

poex T80 series have been produced over the past year and the laboratory tests according to ISO 3451-1:2019 and ASTM D5630 results the same percentage success.

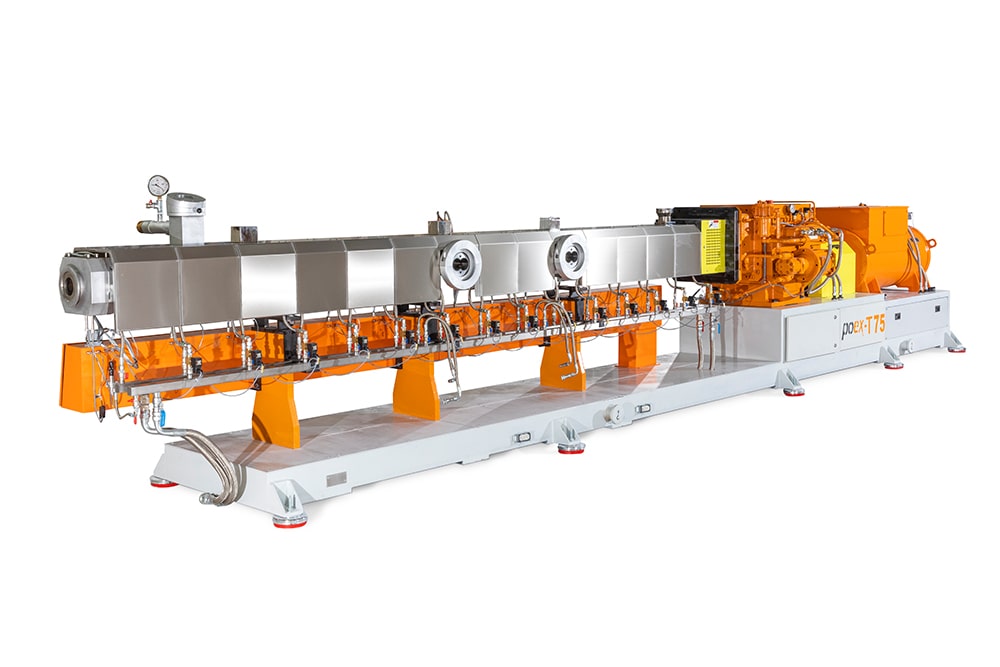

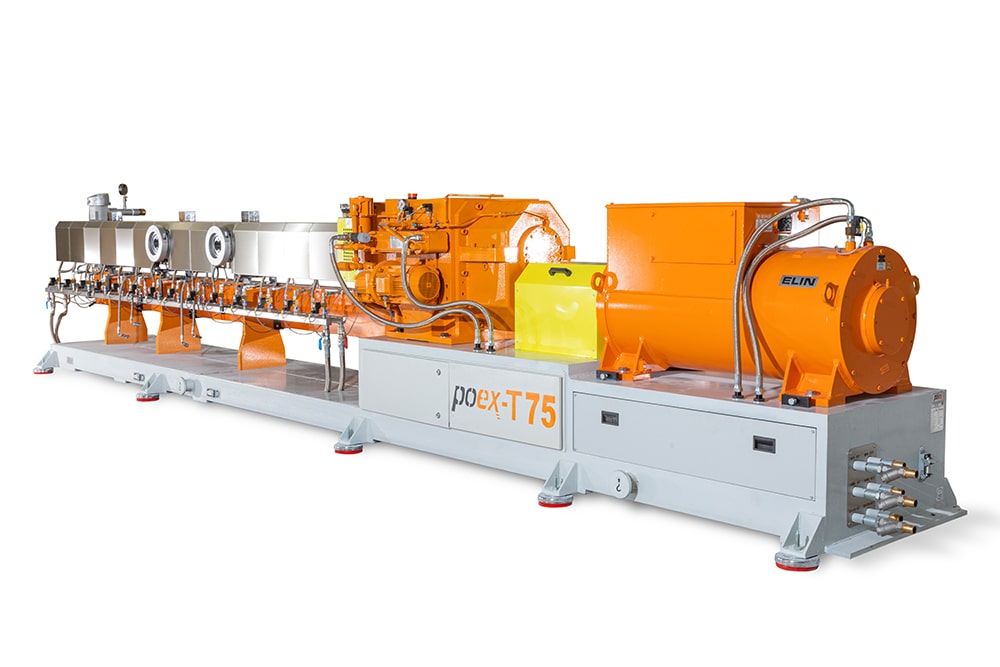

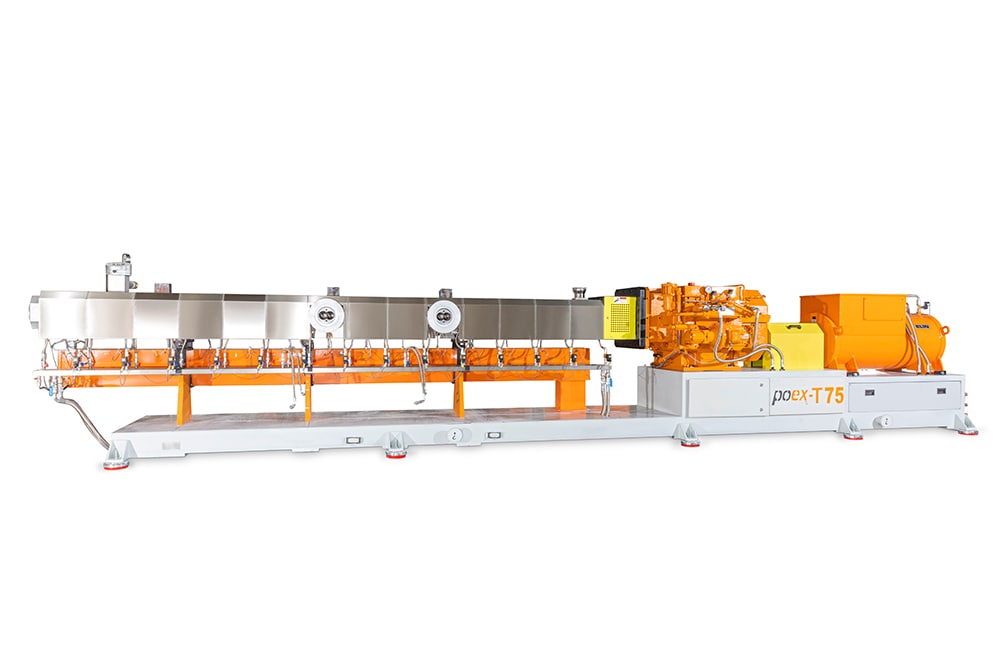

Some of the auxiliary equipment and machine components of the produced poex T80 series extruders are Brabender brand feeders, MAAG brand underwater pelletizers, Elin brand water-cooled stator motors, Zambello brand gearboxes and Mayr brand torque limiters… L/D ratio 52-60, screw diameter 80 mm, Do/Di ratio 1,63; abrasion resistant high qualified steel materials with high qualified labor enable 1400-1600 kg/h capacity (depending on process material) for poex T80 series extruders.

These highly filled PE or PP compounds with a talc or chalk share of up to 83% and these compounds are used in the production of blown film for carry bags, sacks or construction film, for instance. Excellent mixing properties and the high concentration of functional additives that offer unparalleled logistic and economic benefits, highly filled compounds are used to an ever-increasing extent as masterbatches for film and sheet production.

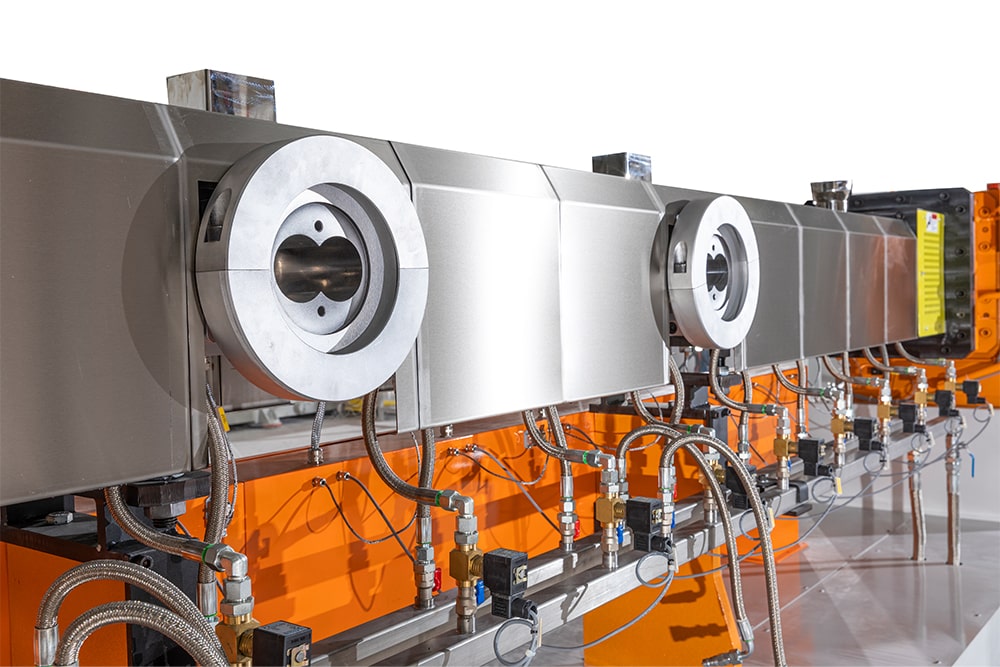

Additionally, the type and number of degassing units are of particular importance for these applications. The introduction of fillers automatically involves the inclusion of air between the particles which is eliminated from the processing chamber by means of three atmospheric degassing systems and one vacuum degassing unit. It goes without saying that the screw geometry is tailored to the specific design of the feed, degassing and mixing zones. The melt pressure required for pelletizing the well homogenized but highly viscous melt is built up by a gear pump of appropriate rating that is arranged at the discharge end of the extruder. The downstream underwater pelletizing system subsequently produces the final masterbatch pellets.

Another subject which poex focused to bioplastics. Polimer Teknik has delivered poex T80 twin screw extruder, gravimetric feeders with material handling, which can be able to produce up to 800 kg/h of mineral filled biodegradable material based on sugar cane.

Moreover, poex T80 size extruder, which is optimally balanced on main feeding port for high volume infeed and has largely free volume of screws with special screw flights, enables low thermal stress on raw material for such a very gently process.

Technical Specifications

| Screw Diameter (mm) | : | 73 |

| L/D | : | 36 –56 |

| Motor Power | : | 300-720 |

| Screw Speed (rpm) | : | 500, 600, 1000, 1200 |

Application Areas

- Engineering Polymers

- Advanced Recycling

- Powder Coating

- Food Extrusion

- High Filled Masterbatch